A Skill, a Choice, and a Gift: MTT Receives a new CNC

by Amber Birckbichler, MTT sophomore

Everyone enjoys unwrapping gifts. The shiny paper, the anticipation of what’s inside -- as children, we could honestly say on the day we opened a gift that it was the BEST DAY EVER! Recently, MTT could relate.

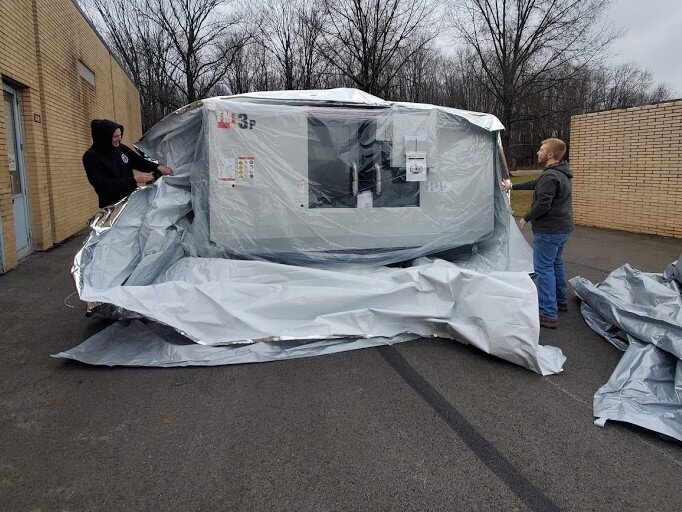

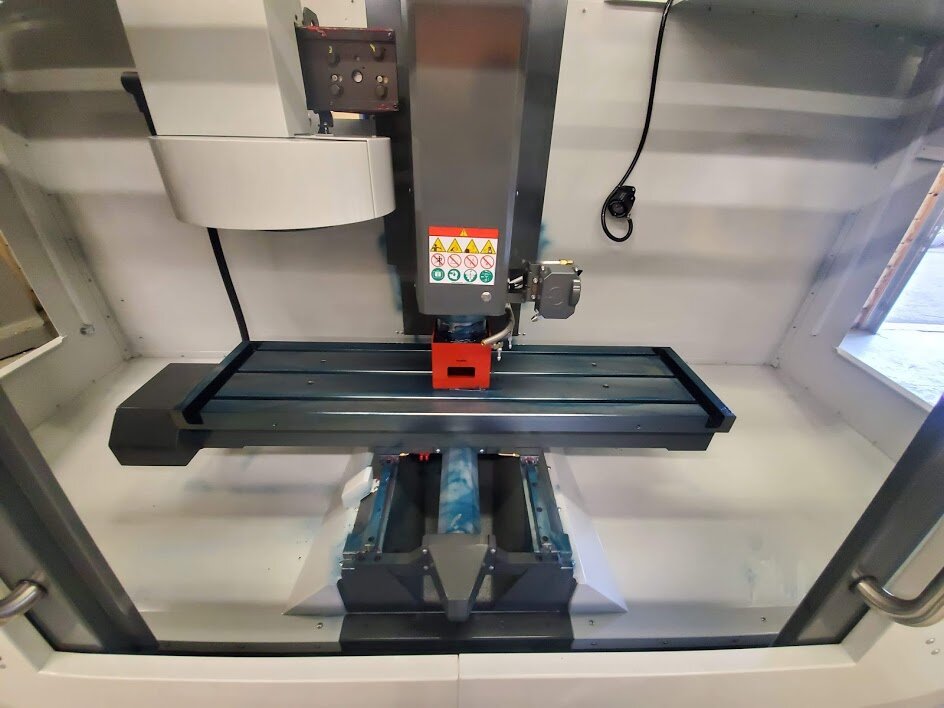

On February 11th, 2020 the machine shop welcomed our new Haas CNC mill which is capable of precision machining and 4th Axis rotary milling as well as bringing our mill programming into modern industry standards. As the semi rolled up the drive, anxious students looked out of the garage doors with eager anticipation. There it was -- wrapped in layers and layers of protective plastic, shining in the winter sun, strapped to the trailer -- our new Haas CNC mill. Our shop was ecstatic when the machine arrived. It was like Christmas -- or the very best birthday ever! A NEW machine! It was T. Bruce Campbell Industries who delivered the mill and put the new machine on a ¾ inch steel plate which they also delivered and put in place to spread the weight on the shop floor.

Getting the new machine into the shop presented a few challenges, but the riggers quickly adapted to the situation. The problem was the size of the garage door compared to the space needed for the forklift and machine; the garage door was too small. The solution: The riggers decided to put it on rollers so they could roll it inside instead. As soon as we got the front half through the door, they put it on 2 rollers, then they pushed the back half in and put it on 2 rollers. Eventually, it was placed on the steel plate.

So with today’s tight budgets, how did this happen? Together, Mr. Miller and Mr. Rich got the new CNC mill on a competitive equipment grant from the state of Pennsylvania. The new machine cost $62,453.00. In addition to the CNC mill, MTT acquired a simulator that came with the new CNC mill, allowing the students the opportunity to depict seven different machine types.

This grant provides MTT with updated technology to learn new machining methods; when our students graduate, they will have the opportunity to have the additional hands-on training and job-ready skills needed to start their career.

Having the new CNC Mill and simulator is a much appreciated gift that will give our students the opportunity to better themselves. Perhaps Brian Herbert understands the gratitude the MTT students feel as he states, “The ability to learn is a skill; the willingness to learn is a choice” but the “capacity to learn is a gift.”